roughing end mill feeds and speeds

Likewise we are here to assist you in determining the correct feeds and speeds starting points based on roughing end mills or finishing end mills you are using. ROUGHING END MILLS Speed and Feed Data Chip Load per Tooth Material SFM 18 14 12 1 Aluminum Alloys 125-250 0010 0020 0025 0030 Magnesium 125-250 0010 0020 0025 0030 Copper 75-100 0008 0015 0030 0060 Brass 85-110 0008 0015 0030 0060 Bronze 75-100 0008 0015 0030 0060 Cast Iron 100-125 0008 0015 0025 0050.

Yg 1 E9990tf High Speed Steel Hss Square Nose End Mill Weldon Shank Tialn Multilayer Finish Roughing Cut Non Center Cutting 30 Deg Helix 4 Flutes 3 875 Overall Length 0 75 Cutting Diameter 0 75 Shank

Feeds - IPT.

. We are here for you. Increase the cutting speed feed rate until the quality of the parts finish starts to decrease or the part is starting to move from hold downs. How to use this calculator.

Of chip load chip lead chip lead chip lead chip lead chip lead chip lead chip lead chip lead end mills rpm per tooth rpm per tooth rpm per tooth rpm per tooth rpm per tooth rpm. I am creating a new calculator based on your feedback. Normally a 20 reduction in effective horsepower is used.

Please contact our very knowledgeable Technical Department at 800-878-0502. SFM 08 Lowest Range Value. This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure.

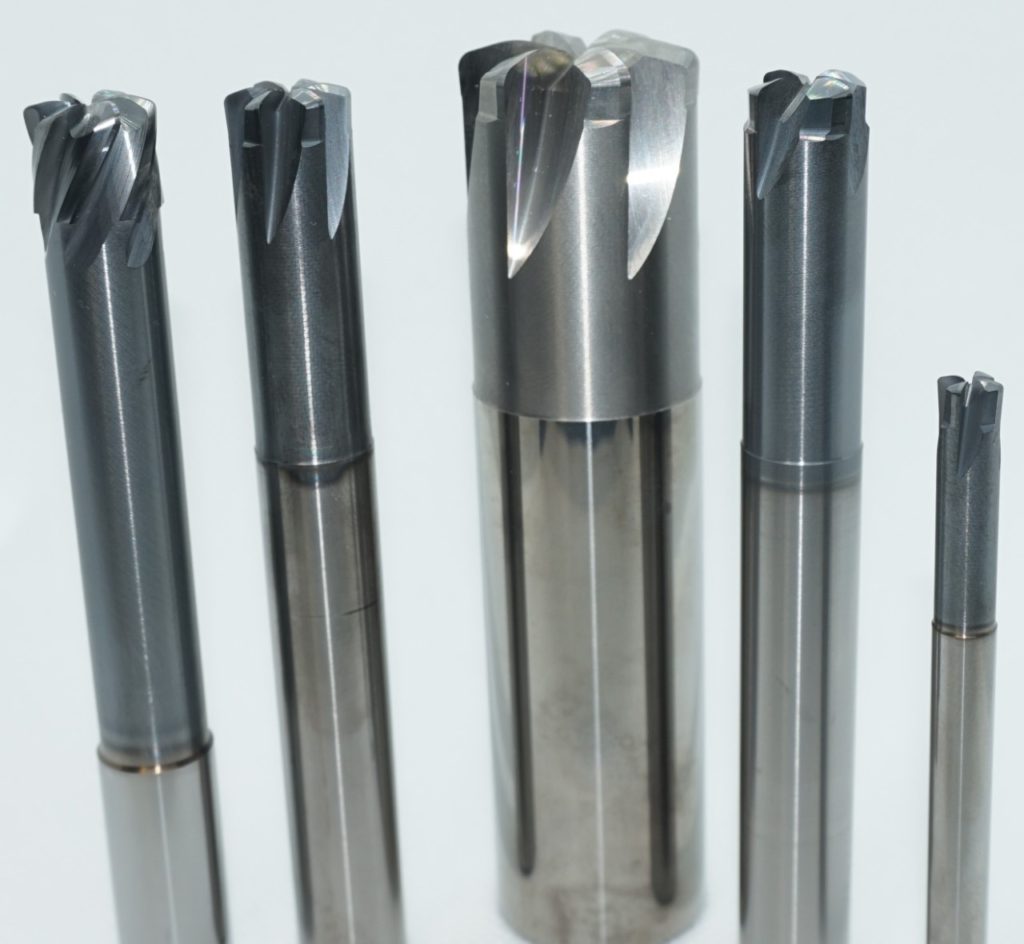

A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation. Now we need feeds and speeds. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

Feed inch inch inch rpm ft min rpm ft min rpm ft min rpm ft min rpm ft min 14 18 38 1900. Our G-Wizard Feeds and Speeds Calculator has special features to help with plunge milling. Higher feed rates are achievable.

These lower the shock load during the cutter rotation both enabling a heavier cutting load. Cart Shopping Cart Toggle navigation. Millimeters Per Revolution MMPR Feed rate of the cutter each revolution of the cutter.

PREMIUM COBALT MILL SPEED FEED Multi-Flute - Side Cutting - Roughing - HSS-C08 End Mills CHARTS Aluminum Aluminum Alloys Material Hardness Diameter 14 516 38 12 58 1116 78 1-18 1-14 1-38 1-34 Carbon Steels Alloy Steels Tool Steels Carbon Steels Alloy Steels Tool Steels. These are our starting parameters only. Our HOG is the perfect addition for new high feed vertical milling software applications.

4 rows SFM and Feed For AD between 025 to 05 of Tool Dia. Higher range of recommended surface speeds should be used For Greater Radial Depths-of-Cut. In the metric system the feed rate of the cutter can be calculated for each revolution of the cutter.

The newly released Machining Central app scans the WIDIA product barcode or searches the tools corresponding order number or an ANSI or ISO catalog number to. PROMAX Premium Feeds Speeds DESIGN-RITE XL Feeds Speeds. SMM SFM X 3048.

Feeds Speeds and Product Dimensional Data in the Palm of Your Hand. Lower range of recommended surface speeds should be used For Slotting Applications. Lets work through an example that shows the strengths of plunge milling.

Ad Discover Products by Brand Type Size. Speed speed speed speed speed speed speed speed speed 5-10 sfm feed 10-15 sfm feed 15-20 sfm feed 20-40 sfm feed 40-60 sfm feed 60-80 sfm feed 80-100 sfm feed 100-200 sfm feed 200-600 sfm feed dia. 38 316 916 1064.

With the aggressive cutting of a variable flute end mill run at 50 for the first few inches to hone the edges for longer tool life. For Lighter Radial Depths-of-Cut. Ships and Delivers Fast.

Then decrease speed by 10. Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use. Chip load x Number of flutes.

Ad Trust Grainger for Quality products at Wholesale Prices. Speeds SFM should be reduced approximately 20 of lowest range value Above recommendations are to be used when axial depth-of-cut does not exceed 1 12. This system is used in all countries that use the Metric system.

516 532 1532 1330. Meters Per Minute MPM The cutting speed of the end mill. End Mill Speed Feed HSS M42 Cobalt.

While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEMHEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. End Mill Speed Feed Calculator.

The spiral flute end mill compared to a straight flute does a similar function. WIDIA has created an app to quickly access machining speeds and feeds for WIDIA tooling without interrupting production. Some end mills with fewer flutes are called roughing end mills as the fewer flutes mean.

Ad For Taps Dies Cutting and Measuring Tools. Suppose we are handed the task of roughing out a pocket that has 18-inche corner radii which dictates and end mill no larger than 14-inch in diameter. Standards Roughers Long Lengths Inch Metric HS Carbide.

Speed and feeds for high speed Steel and Cobalt End Mills. 5 rows End Mill Speeds And Feeds - TiN Coated Carbide. Roughing End Mills - Cobalt and High Speed Steel.

Tipped End Mill 13642 48-005 na na 1 na na na 12 Straight V Carbide Tipped End Mill 13564 48-072 na na 2 na na na 14 Upcut Carbide End. Choose a type of operation drilling reaming boring counterboring face milling slab millingside milling end milling or turning select your stock material choose a material for the tool high-speed steel or carbide input the quantity of teeth for the tool and the diameter of the workpiececutter. Speeds and feeds speeds and feeds for boring tools material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled azamezzehk 2021 thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095 10l45-10l50 12l13-12l15 41l30-41l50 4140-4150.

Speed Feed Recs Melin Tool Company

High Performance Solid Carbide Cutting Tools Promax Premium Design Rite Xl Promax Tools

Colton Cutting Tools 61127 Carbide End Mill 2 Flute Square End Standard 1 16 Diameter X 1 4 Loc X 1 1 2 Oal All Industrial Tool Supply

End Mill An Overview Sciencedirect Topics

Technology Spotlight High Speed Trochoidal Tools

Speed Feed Recs Melin Tool Company

Speed Feed Recs Melin Tool Company

Speed Feed Recs Melin Tool Company

8 Ways You Re Killing Your End Mill In The Loupe

Speed Feed Recs Melin Tool Company

Speed And Feeds For High Speed Steel And Cobalt End Mills

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

Freud 87 308 3 Piece Fine Detail Cnc Router Bit Set Cnc Router Bits Cnc Router Router Bit Set

Speed Feed Recs Melin Tool Company

Kennametal 7 32 Diam 5 8 Loc 4 Flute Solid Carbide Ball End Mill 30524151 Msc Industrial Supply

Speed Feed General Purpose End Mills Melin Tool Company

What To Know When Selecting An End Mill End Mill The Selection Machining Process